[et_pb_section fb_built=”1″ _builder_version=”4.16″ custom_padding=”0px||0px||true|false” global_colors_info=”{}”][et_pb_row _builder_version=”4.16″ width=”100%” max_width=”2560px” custom_padding=”0px||0px||true|false” global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_slider show_arrows=”off” show_pagination=”off” _builder_version=”4.16″ background_color=”rgba(159,176,181,0.48)” max_height=”650px” global_colors_info=”{}”][et_pb_slide heading=”RJG’s TZERO® Solutions” button_text=”Learn More” button_link=”https://rjginc.com/consulting/tzero/#content” image=”https://rjginc.com/wp-content/uploads/2020/06/TZERO-Circle-small.png” image_alt=”TZERO-Circle-small” image_tablet=”” image_phone=”” image_last_edited=”on|desktop” _builder_version=”4.16″ background_layout=”light” custom_padding=”5%|5%|5%|5%|true|true” header_font_size_tablet=”” header_font_size_phone=”32px” header_font_size_last_edited=”on|phone” body_font_size_tablet=”” body_font_size_phone=”18px” body_font_size_last_edited=”on|phone” custom_css_slide_description=”padding:0;||width:55%;” global_colors_info=”{}” custom_css_slide_description_last_edited=”on|phone” custom_css_slide_description_tablet=”width:50%;” custom_css_slide_description_phone=”width:90%;” sticky_transition=”on”]

TZERO® bridges the gap between engineering and manufacturing to predict part quality in a variety of applications. We use various software programs combined with experience to provide an end-to-end solution to assure absolute efficiency during product launch.

TZERO offers comprehensive analyses and unique, case-by-case solutions for each client’s unique challenges. These solutions consist of a combination of comprehensive consultation services, training courses, and technologies. We collaborate with partners around the world, both internally and externally, so each client has the highest level of expertise at their disposal.

If you have questions feel free to contact the TZERO group at tzerocore@rjginc.com

[/et_pb_slide][/et_pb_slider][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ specialty=”on” _builder_version=”4.16″ custom_padding=”||0px||false|false” custom_css_main_element=”display: none;” collapsed=”on” global_colors_info=”{}”][et_pb_column type=”1_4″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_sidebar area=”sidebar-1″ show_border=”off” _builder_version=”4.16″ global_colors_info=”{}”][/et_pb_sidebar][/et_pb_column][et_pb_column type=”3_4″ specialty_columns=”3″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_row_inner _builder_version=”4.16″ global_colors_info=”{}”][et_pb_column_inner saved_specialty_column_type=”3_4″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_text admin_label=”Text: Page Title” _builder_version=”4.16″ global_colors_info=”{}”]

TZERO®

[/et_pb_text][et_pb_blurb title=”TZERO – Art to Part Support” image=”https://rjginc.com/wp-content/uploads/2019/11/TZERO-Circle.png” alt=”TZERO Circle” _builder_version=”4.16″ custom_margin=”||||false|false” custom_css_main_element=”display:none;” custom_css_blurb_content=”margin-left:0px;” global_colors_info=”{}”]

RJG® doesn’t just deliver world class injection molding training and technology, we help make launching tools as painless as possible to ensure good parts from the very first shot.

[/et_pb_blurb][et_pb_text _builder_version=”4.16″ global_colors_info=”{}”]

TZERO® bridges the gap between engineering and manufacturing to predict part quality in a variety of applications. We use various software programs combined with experience to provide an end-to-end solution to assure absolute efficiency during product launch.

TZERO offers comprehensive analyses and unique, case-by-case solutions for each client’s unique challenges. These solutions consist of a combination of comprehensive consultation services, training courses, and technologies. We collaborate with partners around the world, both internally and externally, so each client has the highest level of expertise at their disposal.

[/et_pb_text][/et_pb_column_inner][/et_pb_row_inner][et_pb_row_inner column_structure=”1_2,1_2″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_column_inner type=”1_2″ saved_specialty_column_type=”3_4″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_image src=”https://rjginc.com/wp-content/uploads/2019/11/TZERO-Circle.png” alt=”TZERO Circle” admin_label=”Image: TZERO Circle” _builder_version=”4.16″ global_colors_info=”{}”][/et_pb_image][/et_pb_column_inner][et_pb_column_inner type=”1_2″ saved_specialty_column_type=”3_4″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_image src=”https://rjginc.com/wp-content/uploads/2020/06/3D-Design-Pod.png” alt=”3D-Design-Pod” title_text=”3D Design Pod” admin_label=”Image: Design Pod” _builder_version=”4.16″ global_colors_info=”{}”][/et_pb_image][/et_pb_column_inner][/et_pb_row_inner][/et_pb_column][/et_pb_section][et_pb_section fb_built=”1″ admin_label=”Section: Arrow” _builder_version=”4.16″ background_blend=”multiply” custom_padding=”0px||2%||false|false” custom_css_main_element=”display:none;” collapsed=”on” global_colors_info=”{}”][et_pb_row column_structure=”1_3,1_3,1_3″ admin_label=”Row: Animated Arrow” _builder_version=”4.16″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” collapsed=”on” global_colors_info=”{}”][et_pb_column type=”1_3″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][/et_pb_column][et_pb_column type=”1_3″ admin_label=”Column: Arrow” _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_text admin_label=”Animated Down Arrow” _builder_version=”4.16″ text_font=”|800|||||||” text_font_size=”50px” header_font=”|800|||||||” header_text_align=”center” text_orientation=”center” animation_style=”bounce” animation_delay=”500ms” saved_tabs=”all” global_colors_info=”{}”]

[/et_pb_text][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ admin_label=”Section: Featured Deliverables” module_id=”content” _builder_version=”4.16″ background_color=”#ffffff” custom_css_main_element=” box-shadow: || inset 0px 11px 8px -10px #606060,|| inset 0px -11px 8px -10px #606060;” collapsed=”off” global_colors_info=”{}”][et_pb_row admin_label=”Row: Heading – Featured Deliverables” _builder_version=”4.16″ global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_text admin_label=”Text: How TZERO Transforms” _builder_version=”4.16″ text_orientation=”center” global_colors_info=”{}”]

How TZERO Transforms Your Business

[/et_pb_text][/et_pb_column][/et_pb_row][et_pb_row column_structure=”1_3,1_3,1_3″ _builder_version=”4.16″ custom_padding=”0px||||false|false” global_colors_info=”{}”][et_pb_column type=”1_3″ _builder_version=”4.16″ global_colors_info=”{}”][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”4.16″ global_colors_info=”{}”][et_pb_button button_url=”https://rjg-inc.zoom.us/rec/share/3sF6KKj05HNJAYX07WH2XZV9WbzFT6a813IZrvMJyhlPH0tpfGrsV9hYCO1Md6vm” url_new_window=”on” button_text=”Watch an Introductory Webinar” button_alignment=”center” admin_label=”Button: Webinar link” _builder_version=”4.16″ custom_button=”on” button_text_size=”14″ button_text_color=”#ffffff” button_bg_color=”#00678e” button_border_width=”1″ button_border_color=”#00678e” button_use_icon=”off” custom_margin=”0px|||” custom_padding=”10px||10px|” custom_css_main_element=”width: 100%;” button_text_color_hover=”#00678e” button_border_color_hover=”#00678e” button_border_radius_hover=”0″ button_bg_color_hover=”#ffffff” saved_tabs=”all” global_colors_info=”{}” button_text_size__hover_enabled=”off” button_one_text_size__hover_enabled=”off” button_two_text_size__hover_enabled=”off” button_text_color__hover_enabled=”on” button_text_color__hover=”#00678e” button_one_text_color__hover_enabled=”off” button_two_text_color__hover_enabled=”off” button_border_width__hover_enabled=”off” button_one_border_width__hover_enabled=”off” button_two_border_width__hover_enabled=”off” button_border_color__hover_enabled=”on” button_border_color__hover=”#00678e” button_one_border_color__hover_enabled=”off” button_two_border_color__hover_enabled=”off” button_border_radius__hover_enabled=”on” button_border_radius__hover=”0″ button_one_border_radius__hover_enabled=”off” button_two_border_radius__hover_enabled=”off” button_letter_spacing__hover_enabled=”off” button_one_letter_spacing__hover_enabled=”off” button_two_letter_spacing__hover_enabled=”off” button_bg_color__hover_enabled=”on” button_bg_color__hover=”#ffffff” button_one_bg_color__hover_enabled=”off” button_two_bg_color__hover_enabled=”off”]

[/et_pb_button][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”4.16″ custom_padding=”0px||||false|false” global_colors_info=”{}”][/et_pb_column][/et_pb_row][et_pb_row column_structure=”1_3,1_3,1_3″ make_equal=”on” admin_label=”Row: Featured Deliverables Blurbs” _builder_version=”4.16″ global_colors_info=”{}”][et_pb_column type=”1_3″ admin_label=”Column: Screw Moving Boundary” _builder_version=”4.16″ custom_padding=”15px|15px|15px|15px|true|true” global_colors_info=”{}”][et_pb_blurb title=”Consulting” use_icon=”on” font_icon=”v||divi||400″ admin_label=”Blurb: Consulting” _builder_version=”4.16″ text_orientation=”center” global_colors_info=”{}”]

Combining our decades of design and tool launch experience with a variety of proprietary techniques, we have developed a consultation program to elevate the accuracy of prediction and greatly speed up the tool launch process, getting you to market faster.

[/et_pb_blurb][et_pb_button button_url=”https://rjginc.com/consulting/tzero/consulting/” button_text=”Learn More” button_alignment=”center” admin_label=”Button: Learn More” _builder_version=”4.16″ custom_button=”on” button_text_size=”14″ button_text_color=”#ffffff” button_bg_color=”#00678e” button_border_width=”1″ button_border_color=”#00678e” button_use_icon=”off” custom_margin=”0px|||” custom_padding=”10px||10px|” custom_css_main_element=”width: 100%;” button_text_color_hover=”#00678e” button_border_color_hover=”#00678e” button_border_radius_hover=”0″ button_bg_color_hover=”#ffffff” saved_tabs=”all” global_colors_info=”{}” button_text_size__hover_enabled=”off” button_one_text_size__hover_enabled=”off” button_two_text_size__hover_enabled=”off” button_text_color__hover_enabled=”on” button_text_color__hover=”#00678e” button_one_text_color__hover_enabled=”off” button_two_text_color__hover_enabled=”off” button_border_width__hover_enabled=”off” button_one_border_width__hover_enabled=”off” button_two_border_width__hover_enabled=”off” button_border_color__hover_enabled=”on” button_border_color__hover=”#00678e” button_one_border_color__hover_enabled=”off” button_two_border_color__hover_enabled=”off” button_border_radius__hover_enabled=”on” button_border_radius__hover=”0″ button_one_border_radius__hover_enabled=”off” button_two_border_radius__hover_enabled=”off” button_letter_spacing__hover_enabled=”off” button_one_letter_spacing__hover_enabled=”off” button_two_letter_spacing__hover_enabled=”off” button_bg_color__hover_enabled=”on” button_bg_color__hover=”#ffffff” button_one_bg_color__hover_enabled=”off” button_two_bg_color__hover_enabled=”off”]

[/et_pb_button][/et_pb_column][et_pb_column type=”1_3″ admin_label=”Column: Predictive Template Transfer” _builder_version=”4.16″ background_enable_color=”off” custom_padding=”15px|15px|15px|15px|true|true” global_colors_info=”{}”][et_pb_blurb title=”Training” use_icon=”on” font_icon=”||divi||400″ admin_label=”Blurb: Training” _builder_version=”4.16″ text_orientation=”center” global_colors_info=”{}”]

Training is essential to bridge the skills gap and educate team members on best practices for designs and tool launches. A highly skilled workforce cuts down on rework and speeds up the launch process. These courses use activities to apply coursework to the real world.

[/et_pb_blurb][et_pb_button button_url=”https://rjginc.com/tzero-solutions/” button_text=”Learn More” button_alignment=”center” admin_label=”Button: Learn More” _builder_version=”4.18.0″ custom_button=”on” button_text_size=”14″ button_text_color=”#ffffff” button_bg_color=”#00678e” button_border_width=”1″ button_border_color=”#00678e” button_use_icon=”off” custom_margin=”0px|||” custom_padding=”10px||10px|” hover_enabled=”0″ custom_css_main_element=”width: 100%;” button_text_color_hover=”#00678e” button_border_color_hover=”#00678e” button_border_radius_hover=”0″ button_bg_color_hover=”#ffffff” saved_tabs=”all” global_colors_info=”{}” button_text_size__hover_enabled=”off” button_one_text_size__hover_enabled=”off” button_two_text_size__hover_enabled=”off” button_text_color__hover_enabled=”on” button_text_color__hover=”#00678e” button_one_text_color__hover_enabled=”off” button_two_text_color__hover_enabled=”off” button_border_width__hover_enabled=”off” button_one_border_width__hover_enabled=”off” button_two_border_width__hover_enabled=”off” button_border_color__hover_enabled=”on” button_border_color__hover=”#00678e” button_one_border_color__hover_enabled=”off” button_two_border_color__hover_enabled=”off” button_border_radius__hover_enabled=”on” button_border_radius__hover=”0″ button_one_border_radius__hover_enabled=”off” button_two_border_radius__hover_enabled=”off” button_letter_spacing__hover_enabled=”off” button_one_letter_spacing__hover_enabled=”off” button_two_letter_spacing__hover_enabled=”off” button_bg_color__hover_enabled=”on” button_bg_color__hover=”#ffffff” button_one_bg_color__hover_enabled=”off” button_two_bg_color__hover_enabled=”off” sticky_enabled=”0″]

[/et_pb_button][/et_pb_column][et_pb_column type=”1_3″ admin_label=”Column: Mold Deflection” _builder_version=”4.16″ custom_padding=”15px|15px|15px|15px|true|true” global_colors_info=”{}”][et_pb_blurb title=”Technology” use_icon=”on” font_icon=”||divi||400″ admin_label=”Blurb: Technology” _builder_version=”4.16″ text_orientation=”center” global_colors_info=”{}”]

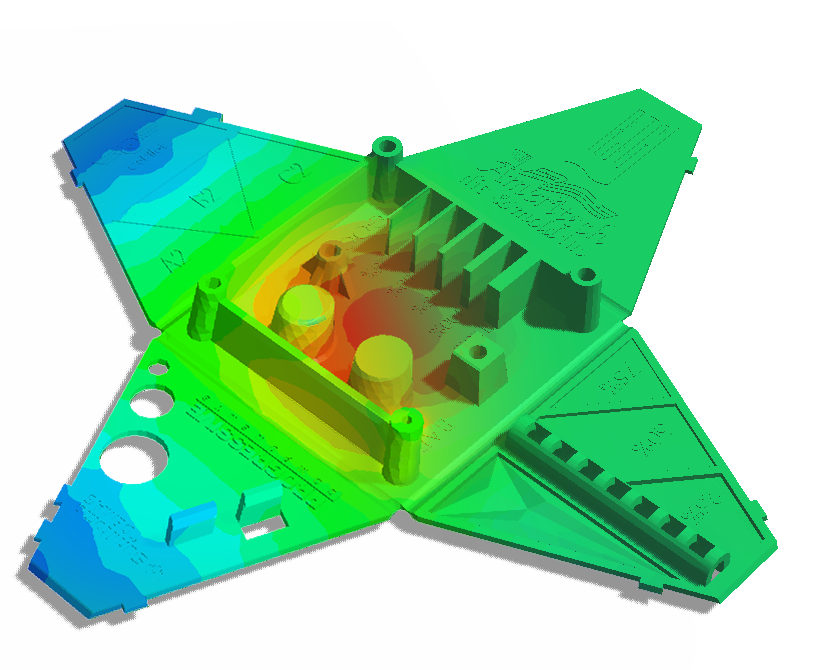

We have invested many years and resources into creating a correlation between sensor measurement data and molding simulations. As a result, we developed a patent-pending methodology to enable you to transfer predicted cavity pressure and temperature to the eDART® system.

[/et_pb_blurb][et_pb_button button_url=”https://rjginc.com/consulting/tzero/technology” button_text=”Learn More” button_alignment=”center” admin_label=”Button: Learn More” _builder_version=”4.16″ custom_button=”on” button_text_size=”14″ button_text_color=”#ffffff” button_bg_color=”#00678e” button_border_width=”1″ button_border_color=”#00678e” button_use_icon=”off” custom_margin=”0px|||” custom_padding=”10px||10px|” custom_css_main_element=”width: 100%;” button_text_color_hover=”#00678e” button_border_color_hover=”#00678e” button_border_radius_hover=”0″ button_bg_color_hover=”#ffffff” saved_tabs=”all” global_colors_info=”{}” button_text_size__hover_enabled=”off” button_one_text_size__hover_enabled=”off” button_two_text_size__hover_enabled=”off” button_text_color__hover_enabled=”on” button_text_color__hover=”#00678e” button_one_text_color__hover_enabled=”off” button_two_text_color__hover_enabled=”off” button_border_width__hover_enabled=”off” button_one_border_width__hover_enabled=”off” button_two_border_width__hover_enabled=”off” button_border_color__hover_enabled=”on” button_border_color__hover=”#00678e” button_one_border_color__hover_enabled=”off” button_two_border_color__hover_enabled=”off” button_border_radius__hover_enabled=”on” button_border_radius__hover=”0″ button_one_border_radius__hover_enabled=”off” button_two_border_radius__hover_enabled=”off” button_letter_spacing__hover_enabled=”off” button_one_letter_spacing__hover_enabled=”off” button_two_letter_spacing__hover_enabled=”off” button_bg_color__hover_enabled=”on” button_bg_color__hover=”#ffffff” button_one_bg_color__hover_enabled=”off” button_two_bg_color__hover_enabled=”off”]

[/et_pb_button][/et_pb_column][/et_pb_row][/et_pb_section]